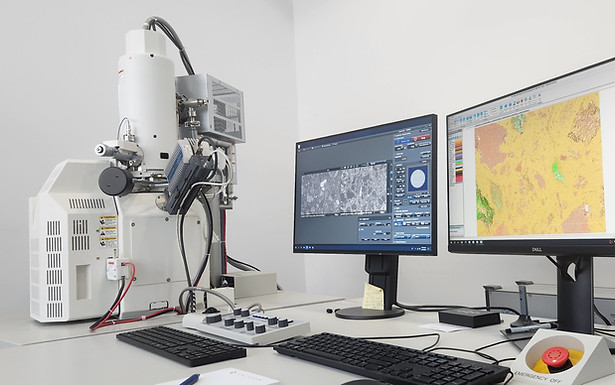

SEM: Hitachi SU3900

The Hitachi SU3900 scanning electron microscope is our workhorse instrument. Its extremely large chamber gives us the flexibility to load multiple samples or, if required, we can image samples in excess of 200 mm in diameter.

Custom-designed holders allow us to routinely measure resin blocks, thin sections, and even slabs of core.

It is fitted with twin energy dispersive spectrometers for automated mineralogy, rapid spot chemical analysis, elemental mapping, or quantitative microanalysis.

A range detectors are mounted including secondary electron (SE), back scattered electron (BSE), and a variable pressure SE detector that is also configured for cathodoluminescence (CL) imaging.

FEG-SEM: Hitachi SU5000

The SU5000 field emission gun (FEG) scanning electron microscope is a versatile platform capable of imaging at very high magnifications and resolutions.

Custom sample holders allow us to routinely measure resin blocks, thin sections, as well as standard SEM stubs and grain mounts.

It is fitted with twin energy dispersive spectrometers for automated mineralogy, rapid spot chemical analysis, elemental mapping, or quantitative microanalysis.

A range detectors are mounted including secondary electron (SE), in-column SE, back scattered electron (BSE), and a variable pressure SE detector that is also configured for cathodoluminescence (CL) imaging.

Ar Ion Mill: Hitachi IM4000II

Mechanical polishing is sufficient for most applications but it can introduce micron-scale (or smaller) deformation in the sample. For very high resolution FEG-SEG imaging of specific sample types, a defect-free surface is preferred.

Argon ion milling uses a focused beam of Ar to ablate the sample surface and create a defect-free "polished" surface. Although the beam looks like a focused flame, it is not hot and therefore sensitive materials such as organic matter are not damaged during milling. Indeed, imaging porosity in organic matter is one of the major application areas of this preparation technique.

Polishers

As automated mineralogy requires a steady stream of polished epoxy mounts, we have optimised the preparation workflows so that hundreds of samples can be prepared each week. Our laboratory therefore has a range of polishing equipment that allows us to quickly and easily prepare epoxy resin blocks for analysis.

In addition to preparing automated mineralogy samples, we offer a stand-alone preparation service where we embed samples in epoxy resin and make polished blocks 30 mm in diameter. Samples don't have to be geological in nature; we have prepared many different materials from electrodes through to coupons of metal tubing.

For thin section preparation, we work closely with our trusted partners.